About us

We are the only Russian company that is exclusive distributor of equipment for GE, Philips, and Siemens.

We have certificates for our production in accordance with the ISO 9001 and ISO 13 485 standards, as well as a license to service medical devices.

We have certificates for our production in accordance with the ISO 9001 and ISO 13 485 standards, as well as a license to service medical devices.

RF Door

The shielding door of the RF room is a necessity that ensures the safety and accuracy of the diagnosis for patients undergoing examinations inside the MRI machine.

RF Window

RF Window for an MRI scanning area is a specially designated space designed to provide a safe and comfortable environment for patients and healthcare professionals during magnetic resonance imaging (MRI) scans.

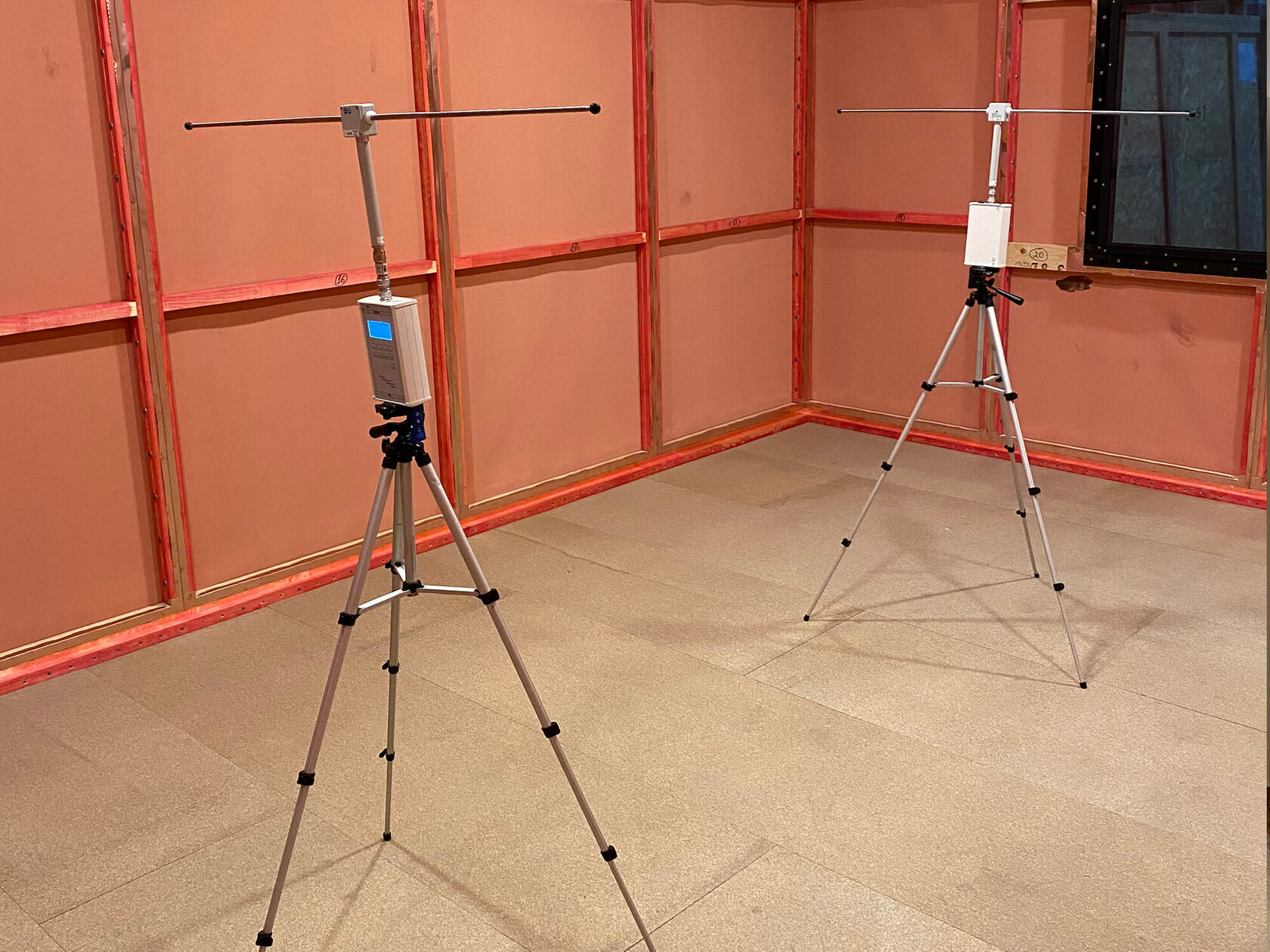

Measurement of shielding effectiveness (RF test)

The shielding efficiency of a Faraday cage measures by comparing the intensity of the electric field inside the cage (Ii) with the intensity of the external field (Io). The ratio is called the shielding factor (K) and is expressed in decibels

K = 20 * log (Io / Ii)

K = 20 * log (Io / Ii)

Magnetic shielding (passive protection)

A magnetic shield is used to protect people from the magnetic fields generated by an MRI machine. The shield is made from specialized steel that blocks the flow of the magnetic field.

RF filters

- Ventilation cell filters

- Electric RF filters for power supply input and signal cables

- Filters for medical gas introduction

- Copper contact springs for RF doors (slats)

Quench pipe

The emergency helium release system is essential for discharging helium safely and quickly in case of an emergency. It allows for quick and secure discharge of the gas, preventing it from causing harm to human health or damage to equipment.

Stages of work

Production

Based on individual dimensions with the usage of fire-resistant and noise-absorbing materials.

Stage II

Mounting

Mounting is carried out by qualified technicians with extensive experience in installation of RF cabins (Faraday cages).

Stage III

Project

Preparing a 3D layout

Production

Based on individual dimensions with the usage of fire-resistant and noise-absorbing materials.

Mounting

Mounting is carried out by qualified technicians with extensive experience in installation of RF cabins (Faraday cages).

Stage I

Stage II

Stage III

Implemented projects

years in the industry

10

projects

500+

We provide a wide range of services and ensure our clients receive the best results, full compliance with building code standards and regulations, as well as efficiency, high productivity, and cost-effectiveness of the equipment used in climate control systems.

They work with us

Leave a request

We will contact you as soon as possible

By clicking on the button, you consent to the processing of your personal data and agree to our Privacy Policy

Leave a request

We will contact you as soon as possible

By clicking on the button, you consent to the processing of your personal data and agree to our Privacy Policy

Let's discuss your project

We will contact you as soon as possible

By clicking on the button, you consent to the processing of your personal data and agree to our Privacy Policy